News / Exhibitions

Experience with the use of VLSFO after 1 Year

Technical Update

“ Experience with the use of VLSFO after 1 Year.”

With the IMO 2020 regulations already in effect on January 1st. 2020, there has been a dramatic shift in the dominant bunker fuel, shifting from Heavy Fuel Oil (HFO) to the new 0,5% Sulphur Very Low Sulphur Fuel OIL ( VLSFO).

After one Year of usage of the VLSFO, many experience reports by institutes and operators are meanwhile available.

Although the change has seemed relatively smooth regarding availability and prices,

the reports show that the initially fears regarding stability and incompatibility problems of the blended VLSFOs are confirmed and not solved yet.

It was reported that instability of VLSFOs lead to:

Sludge accumulation in the storage tanks, piping systems or centrifuges and filters causes purifier and filter chokes.

Compatibility issues lead to:

Formation of flocculation or separation of asphaltenes, precipitating sludge, blocked filters and separators.

On the engines increased wear and tear, higher black carbon emissions and even

Fires in engines were observed.

All those reported problems were caused by the fact that the blended VLSFOs are of inhomogeneous structure. To solve these problems it is necessary to homogenize the VLSFO.

“The mechanism of the blending process itself is equally important. The components must be completely homogenized, and this is extremely difficult to achieve without efficient blending equipment.” Shell brochure “Bunker Quality”

By using the LR and BV approved S.I.T CD92 Homogenizer, the inhomogeneous, instable and incompatible VLSFOs easily can be converted into homogeneous, stable and compatible structure, so that reported problems will not any longer occur.

If you are interested to hear how it works, please feel free to contact us and we can send information material or do a Skype Technical Presentation.

Brgds, Heino Stache[Skype: Heinzicd92

IMO Survey Report Regarding VLSFO experiences published

Experiences with the use of compliant ( VLSFO) fuel oil.

IMO recently published a survey in which they have asked several ship operators about their experience by using VLSFO respective compliant fuel.

The results have shown that the fears about risks of using incompatible VLSFO which were raised last Year, were justified and are confirmed now.

Sulphur, sediment the main issues in IMO 2020 transition, survey finds:

“The transition to IMO 2020 compliant fuel oil (0.5% sulphur) has not been without problems, with sulphur content, sediment, and aluminium plus silicon being the main issues experienced, a recent survey found.”

Main findings

More specifically, 62% of the respondents have to some extent experienced increased sludge deposits in the fuel oil system including increased sludge discharge from the ship’s separators.

32% of the respondents answered that they had experienced wax appearance in the fuel oil system e.g. in fuel oil tanks, filters etc.

31% of the respondents answered that they had experienced operational issues caused by increased wear and tear of cylinder liners, piston rings or other components, assessed to be due to increased amounts of catalytic fines (cat fines) in the fuel oil.

22% of the respondents answered that fuel oil had been de-bunkered as a consequence of fuel oil properties.

21% of the respondents answered that they had experienced problems with fuel injection, poor ignition or incomplete combustion of the fuel.

18% of the respondents answered that they had experienced fuel oil pumps seizures.

10% of the respondents answered that they had experienced loss of propulsion and/or black out as a consequence of fuel oil properties.

The answers and comments provided by respondents suggest that the transition to IMO 2020 compliant fuel oil (0.5% sulphur) has not been without problems. As fuel oil properties are fluctuating, quality and safety problems will continue to be a challenge for the global shipping industry.

All above mentioned problems are caused by incompatibility of the VLSFO mixture and can be eliminated when VLSFO will be homogenized.

In order to learn how it works, please contact us:

e.mail: service@sit-hamburg.de ; skype: heinzicd92

Read more … IMO Survey Report Regarding VLSFO experiences published

Skype technical presentation available

Due to Covid-19 it is currently almost impossible to travel through the world and to introduce technical systems to potential customers.

On the other side we recognized a huge demand for technical introduction of our systems, because the implementation of the new MARPOL/IMO 2020 low sulfur cap regulation, has caused many operational problems to Bunker supplier and shipowners/managers.

The problems caused by incompatibility of VLSFO are easily resolvable if S.I.T CD92 Homogenizers are used.

Also for ships equipped with Scrubbers the CD92 units offer a solution to reduce technical problems and operation costs.

How this works can be demonstrated by our technical Power Point presentation.

In order to present this it is not necessary that we travel to your place, the presentation can be easily done via skype video conference as well.

All you need is a Skype account.

If you are interested to hear how the installation of our CD92 systems can solve your problems caused by using VLSFO or Scrubbers, please just contact us and we appoint a sufficient time to do the presentation.

Please contact us under: e-mail: service@sit-hamburg.de or skype: heinzicd92.

Brgds

Heino Stache

New IMO-PAS "Publicly Available Specification" confirms risks of incompatibility when VLSFO is used.

Since the new MARPOL 2020 sulfur cap regulations were published experts are warning to the risks of incompatibility when Very Low Sulfur Fuel Oils (VLSFO) are used.

The fears are:

1.)Blended VLSFOs are a mixture of minimum 2 different fuels like distillate and HFO with different densities and viscosities.

Due to these different densities and viscosities the blended VLSFO will fall apart during storage in the Tanks because the components of higher density and viscosity are bigger and heavier than the light and small distillate droplets. Due to force of gravity the bigger and heavier HFO components will separate and sink down to the bottom of the tanks.

2.) Recently a CEO of a leading Shipmanagement said in an interview:

" If your C/E puts a low sulfur fuel on top of another low sulfur fuel and they are incompatible you can have a catastrophic engine failure, you can have vessel breakdown at sea, you can have all sorts of huge problems"

Since it is impossible always to empty the Tanks before you refill them with new VLSFO it will happen that there will be a mixture of two different VLSFO supplies with different densities and viscosities in one tank.

These fears are now confirmed by recently published IMO PAS 23263-2019.

In the PAS it is confirmed that the VLSFOs will be a blend of different fuels with a density of abt. 870kg/m³ and 997kg/m³.

It is also stated in the PAS under item 11:

" Already 100s of VLSFO samples have been tested and typically viscosity falls in the range of 10 to 380 cSt and density from 870 to 991 kg/m³.

This proves that the fears are founded that the delivered VLSFOs will be incompatible and that two different VLSFO in one tank will be incompatible as well.

The new ISO says that the supplied VLSFO must comply with the max. 0,5% sulfur content regulation but in the ISO 8217 specification the density and viscosity of the VLSFO are NOT regulated.

Therefore it is very likely that VLSFO of maybe 870kg/m³ will be mixed with existing VLSFO in the tanks with a density of 997kg/m³.

IMO and ISO says that the crew has to manage such problems.

These incompatibility problems easily can be solved if the VLSFOs are homogenized via S.I.T`s CD92 units.

If you want to hear how it works, please feel free to contact us. We will send more information material or visit you at your premises and do a technical presentation if requested.

Heino Stache, MD S.I.T GmbH

Skype: heinzicd92

MARPOL 2020 sulphur cap

Since it became known that from January 2020 on a new reguleation will come in force which has the aim to reduce the sulphur emissions, experts evrywhere in the world are discussing about the rise of costs and risks.

S.I.T wins order to deliver 30 x CD92SR systems

S.I.T wins order to deliver 30 x CD92SR systems

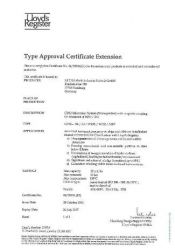

Extension of Lloyds Register Type Approval

Extension of LR Type Approval for CD92 Systems issued

New website online!

In order to ease the communication between people interested in our products and S.I.T, we have decided to totally modify our website presentation.

Invitation - SMM 2012 International Trade Fair Shipbuilding, Machinery & Marine Technology,

Visit us on the SMM trade fair in Hamburg Hall A1 Booth 323.